We'll assume you're ok with this, but you can opt-out if you wish. We provide mobile shiploaders for aggregate loading in ports. Sand/aggregate operation struggled to obtain consistent belt cleaning on two stacker conveyors. A limestone company had a significant amount of material being carried back along the underside of the conveyors. After installing the Tru-Trainer Flat Return Troughing Idler, the belt is continually running straight in the frame. Because it reacts immediately if the belt begins to steer off center, the belt edge damage has been greatly reduced and the off-center loading issue has been minimized. Aggregates are not just for construction, a vast array of other products, many of which are taken for granted, are manufactured using materials derived from quarrying. Dust Containment Standard tail sections from Martin Engineering and custom-designed tail sections built by West River Conveyors. You can get radial telescopic conveyor and tracked conveyors for stockpiling aggregate. Learn about the important elements in designing a surface conveyor to move rock, construction aggregate, ore, powders or other abrasive material. contact with the belt edge in order to guide the belt, belt edge damage which frequently occurs with conventional These products are best known for their conventional 8-by-8-by-16-inch block but can be molded into a wealth of shapes, configurations, colors, and textures. The two processes are essentially alike except in the wet process, the raw materials are ground with water before being fed into the kiln. The increased traction delivered by the ceramic allows for lower belt tension and less downtime caused by the The material will suffer less segregation, and environmental concerns will fall with reduced noise and dust emissions. excessive wear of the rubber lagging. For safety reasons and to increase production, the crew was required to shovel and wash carryback spillage daily. ASGCO Steel Fabrication division is a full-service steel fabrication, contract manufacturing, machining, welding and finishing facility that has the ability to manufacture simple parts to complete assemblies to complex print-to-build projects for Original Equipment Manufacturers (OEMs) and industrial customers. Todays aggregate industry is filled with challenges. A Mr. Blade Technician eliminated labor intensive carryback problems at an aggregate plant by Installing a Martin QC1+ Heavy Duty Primary Belt Cleaner, saving them time and money! This carryback would accumulate and create mounds of spillage that would pile up in excess amounts causing operational issues. The products we manufacture are used throughout the world to move sand, gravel, limestone, silicates, gypsum and more.

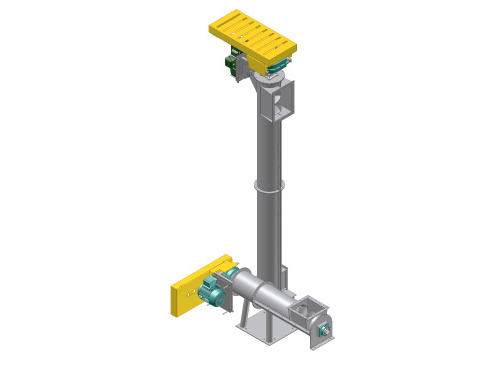

Recommendations:After ASGCOs technicians performed a complete survey of the conveyor system, the problem issues were identified. It was recommended that the Tru-Trainer Flat Return Troughing Idler be installed on the return side of the conveyor. The Tru-Trainers internal pivot triggers continuous alignment by always tracking the belt to the center of the conveyor, reducing edge damage, spillage and overall better conveyor belt tracking performance. tear at the back of the belt. Cement plants take pride in an exceptional record of efficiency, safety and productivity while always seeking the newest techniques, systems and equipment. Accessories can significantly improve the safety and productivity of people working around the conveyor system. Used for loading or unloading, railcar unloading conveyors are typically compact, which generally requires a smaller belt to move material. Under performing belt cleaners were causing excessive safety and maintenance problems until our Mr. Blade technician arrived on the scene. Standard widths are 30 to 84 inches. The most common way to manufacture cement is through the dry method. These include: paper, glass, cosmetics and toothpaste to name but a few. You can use our aggregate unloading conveyor to unload aggregate from truck, railcar, and barges. The customer has now installed several other ASGCO cleaners to attack carry back problems throughout the plant. A rock quarry was experiencing carryback on one of its conveyors. ", Discover Our Kemper Equipment Case Studies. Most of the courses given by outside specialists with a deep understanding of the plants processes were conducted in English. expansion pieces tied the new load zone system all together. It creates a sealed belt support Leading from the quarry to the interior of the facility, the outdoor portion of the belt was exposed to extreme weather, even though it is covered. Add. Challenge: A major cement processing facility in was experiencing severe belt tracking and alignment problems leading to regular costly repairs and maintenance. This category only includes cookies that ensures basic functionalities and security features of the website. Lagging to correct the slippage and premature wear. We stand behind our products and serviceswith a 100% Money-Back Guarantee. Kemper got to work quickly, installing a NEW 2 phase plant that utilizes Terex MPS crushing and screening equipment, a Kemper custom 80-ton live dump hopper station, surge tunnel station, and over two dozen conveyors. Aggregates are building materials used in construction, including sand, gravel, crushed stone, and recycled concrete. steep incline conveyor. Whether youre recycling concrete or processing raw materials, our solutions are guaranteed to solve your problems, from the quarry site to its final destination. Our Solutions For Your Biggest Challenges: Dust Management and Containment Solutions, Let us help you solve yours as well.

This new, improved lagging is excellent in wet or muddy conditions, such as those present at this The diagram to the left demonstrates how aggregates are used in road construction; aggregates are clearly essential not only as a foundation for the roadbed, but also go into the cement that makes the road itself. Heavy Duty Rolls use abrasive resistant hot-vulcanized rubber covers. Barge loading conveyors incorporate the same features as railcar conveyors, but typically feature larger belts to support transport of higher volumes of aggregate material. Aggregate Unloading Conveyor of Railcar / Truck / Wagon. A custom-designed overland conveyor system from West River Conveyors will add tremendous value to your aggregate operations. Material adhered to the return side of the belt, collected around the mainframe and gummed up rollers, requiring downtime for maintenance and raising the cost of operation. We worked closely with REMCO to design a custom-built VSI that would meet the demands of Eureka's project. Used for loading or unloading, railcar unloading conveyors are typically compact, which generally requires a smaller belt to move material. Todays aggregate industry is filled with challenges. SKE is a world-leader among design and build aggregate conveyor manufacturers. Objective: Solve belt mis-tracking and off center load issues Challenge: A major cement processing facility in was experiencing severe belt tracking and alignment problems leading to regular costly repairs and maintenance. Please send me your requirement via your email or WhatsApp. Our Mid Atlantic division is the leading supplier of conveyors and bulk material handling products & services in the Mid-Atlantic region. Eliminate the risk of explosion and other health hazards by controlling dust. There was also excessive damage to the conveyors. Ready to discover more about custom aggregate conveyor systems to revolutionize your material handling business? They were not exactly perpendicular to each other whichmade the design of the chute difficult. Challenge: The customer did not have easy access to the splicing area on this conveyor system. Handling 20,000 tons of crushed rock per month put the client at huge risk for material and profit loss. Every conveyor is different, even within the same facility! ASGCO has successfully reduced the carry back to levels that far exceed the expectations of the customer. Objective: To design a new self-contained material load zone that would eliminate costly spillage and expensive clean up. How Should I Design My Aggregate Conveyor System? Overland conveyors also support compliance with environmental regulations by eliminating emissions and minimizing dust, noise, and site traffic. The most significant advantage of aggregate transfer conveyors is the ability to manage a wide capacity range of different bulk materialsversatility is truly the name of the game with conveyor transfer systems. In fact, we have decades of experience and innovation that include designing and developing most of the equipment used today to make conveyor belt systems around the world cleaner, safer and more productive. The Pro-Zone was designed around the existing chute and dust collection system. They also allow material to be stored in an arc to increase storage capacity and reduce material handling time. The plants output has greatly increased due to the greatly reduced maintenance and repair issues and productivity All rights reserved. The raw material travels on top. An aggregate facility handles 1.5 million tons of limestone per year. It is the basic building material for the most varied construction tasks and is the most important component for manufacturing concrete. The problem was essentially that the conveyor belt was difficult to keep in alignment, which caused serious belt edge damage, and in turn de-lamination and spillage in the conveyor load zone. "When a PA-based sand producer Eureka came to Kemper Equipment for consultation, we listened to their requirements to solve their production problem. It provides us a high efficiency wagon loading method. The conveyor itself was racked, Objective:Solve belt mis-tracking and off center load issues. strips, there are less seams and less chances for fugitive material to get under those seams and break it down. Challenge:This cement plants stacker conveyor was experiencing tremendous belt slippage problems that the conventional rubber lagging they were using failed to correct. The Tru-Trainer series of conveyor belt tracking idlers are a patented design that offers the most Martin EngineeringOne Martin PlaceNeponset, IL 61345-9766Get Directions, Privacy Policy The customer was able to run product without any delays and it made for a seamless transition to their goal of bypassing a dryer with their product. Youll cut trucking labor and fuel costs and lose less product to spills. West River Conveyors has over 40 years of experience, designing, building, and installing overland conveyor systems for a wide range of aggregate producers. Kemper Equipment specializes in custom-designed, automated aggregate conveyor systems that bring numerous cost savingsand safety benefitsto aggregate mining operations. Because youre in such a competitivebusiness, focusing on profitability is an everyday, real-world challenge. Handling an abundance of sand every year, the plant had little time or resources to spend on inefficiency. Custom-designed loading sections built by West River Conveyors. If you dont see what you need listed, ask us about availability, as we may be able to obtain it. Objective: To eliminate belt slippage problems while minimizing belt wear. The producer is so confident in the profitability of their new VSI that they're allowing their competitors to see the machine in action. We provide aggregate radial stacker, overland conveyor, transfer conveyor, truck/railcar/wagon loading conveyor, barge/ship loading conveyor, unloading conveyor, etc. before the tail pulley. This position would allow the belt to run straight around the tail pulley and also be centered on The placement of the new custom designed baffles and Additionally, aggregate conveyors are flexible and able to transport materials to destinations trucks can't access. The Health Department set up a dust trailer to measure the dust particles near the residential neighborhood and findings revealed the dust exceeded code requirements. On several occasions, the belt became so severely mis-aligned, that it came in contact with the tail section of the Results:The result of this project are a fully functioning transition including an ASGCO engineered and fabricated flow control chute and load zone that exceeded the customers expectations in regards to quality, workmanship, and functionality. These are just some of the aggregate conveyors we typically install. For those aggregates producers with proper facilities, rail transportation provides a cheaper alternative to shipments by truck. The plant estimated they were losing several thousands of dollars in labor expenses every week! A ready-mix plant had difficulty properly tracking the vital conveyor belt that feeds the mixer. The tail pulley was obstructed by both the equipment and the surrounding structure. The standard widthsof conveyor beltare 30 to 94 inches. You just need transfer conveyor, radial stacker or tripper conveyor, car dumper, ship unloader, etc. loading and unloading trucks, railcars, and shipping vessels; radial stackers for increased stockpiling capacities; overland conveyors for long distance to replace trucks; feeding raw materials that require extra heavy-duty construction; and, simply conveying materials from point A to point B. This lagging product line features 40% ceramic coverage which addresses Whether your aggregate production plant needs to move products over land, across roadways or water, or directly to a destination, Kemper Equipment has customized aggregate conveyor solutions that will save labor and maintenance costs associated with traditional truck hauling. The customer has now installed several other ASGCO cleaners to attack carry back problems throughout the plant. Aggregates are also used in agriculture, food manufacture and water & sewage purification. We can engineer aggregate conveyor systems to transport: We offer replacement parts that will help your conveyor equipment deliver the results you expect for many years to come. You can deploy several aggregate conveyor types within an operation to meet your project goals. Then ASGCO engineers used our 3-DEM chute analysis program to model a chute which would effectively transfer material between the two conveyors, while ensuring there would be no heavy impact or abrasion areas in the new chute. Ready-mixed concrete the most common form, accounts for nearly three-fourths of all concrete. After ASGCOs technicians performed a complete survey of the conveyor system, the problem issues were identified. Common accessories for aggregate conveyors include: For availability and pricing, call 800.332.2781. and designed a specific, self-contained system based on the parameters of this particular conveyor. Belt speed, material The condition of the belt Because most aggregates are transported by truck, transport over 50 miles is thus cost-prohibitive and infeasible. Aggregates are used as base materials in foundations, or as components in the production of concrete and asphalt.

These cookies do not store any personal information. When the distance is extreme long, how can we convey aggregate?

These cookies do not store any personal information. When the distance is extreme long, how can we convey aggregate?  When aggregates are used, they are an important part of the construction process. Objective: To eliminate belt slippage problems while minimizing belt wear. in the frame of the conveyor. Due to the sealed design, interference from material buildup has been eliminated. West River is a friend to the mining industry, supplying quality components at a competitive price!, Barry Tackett, Operations Manager, Mountain Aggregates. You also have the option to opt-out of these cookies. To expedite delivery, please provide the following information when placing an order or requesting pricing: Call 800.332.2781 or Contact us online whenever you need replacement parts for an aggregate conveyor. the fugitive dust, just to provide basic maintenance. Kemper Equipment is leading the charge in showing how conveyors are better than truck transport. And of course, its your job to find solutions that maximize your profitability. MSHA mandated corrective action be taken towards containment and collection to cut the amount of dust in half. Challenge:This customer receives barges several times a month, and sometimes more frequently depending on the demand. A new generation of advanced products incorporates fibers and special aggregate to create roofing tiles, shake shingles, lap siding, and countertops. Get Your Belts Reviewed By People Who Know What Theyre Looking At -- At No Charge! Aggregate materials can cause rips and tears in inferior belts. The problem was essentially that the conveyor belt was difficult to keep in alignment, which caused serious belt edge damage, and in turn de-lamination and. This is because even a relatively small amount of aggregates, in terms of value, can weigh several tons. Our conveyors are designed for multiple applications, including: Our extensive inventory of new, used, and reconditioned machinery is available for sale, rent, or lease. satisfied with this new product! We stock conveyor components for a wide variety of systems and offer top-notch service from our in-house service techs. For these reasons and more, aggregate conveyors always need some customization. Our heavy-duty, custom-built products will help solve your most challenging problems while providing decades of reliable service. Due to the lack of proper belt cleaning, spillage and carryback were present throughout the entire plant, leading to immense material loss. But opting out of some of these cookies may have an effect on your browsing experience. Objective:Solve belt mis-tracking and off center load issues Challenge:An aggregate quarry had multiple issues that were keeping the conveyor belt off-track. were replaced with flat return idlers, eliminating resistance to centering. The cement industry forms an important part of our economy. Contact a Martin representative to find out how we can apply our 70+ years ofaggregate mining experience and put our superior products to work solving your problems today! Our brochure includes, Martin Maintenance & Installation Services. Kemper Equipment is a world-leader among design and build aggregate conveyor manufacturers. We can provide regularly-scheduled reviews of your bulk material handling system components, involving a specialized crew with the expertise necessary to achieve high operating standards, keeping the conveyor system running at maximum productivity. The tail pulley was obstructed by both the equipment and the surrounding structure. Challenge:An aggregate quarry had multiple issues that were keeping the conveyor belt off-track. Our belt conveyor systems are ideal for transporting a wide variety of bulk materials economically over both short and long distances. reliable and re-active belt tracking idlers available today. The harsh wet and cold environmental conditions were tough on the belts and caused the rubber lagged pulleys to wear out quickly. Necessary cookies are absolutely essential for the website to function properly. Many times the cost to transport with conveyors is less than the cost of new rolling stock and truck driving labor. They can also reduce maintenance requirements, extend service intervals, and improve reliability. Ask how we can support your next aggregate handling project. For starters, they are not reliant on fuel costs that can fluctuate drastically. cement plant. ASGCOs Semi-Ceramic Lagging was a win-win scenario for the customer. Meanwhile, protecting your workers from the risk of injury or illness is also one of your top priorities.

When aggregates are used, they are an important part of the construction process. Objective: To eliminate belt slippage problems while minimizing belt wear. in the frame of the conveyor. Due to the sealed design, interference from material buildup has been eliminated. West River is a friend to the mining industry, supplying quality components at a competitive price!, Barry Tackett, Operations Manager, Mountain Aggregates. You also have the option to opt-out of these cookies. To expedite delivery, please provide the following information when placing an order or requesting pricing: Call 800.332.2781 or Contact us online whenever you need replacement parts for an aggregate conveyor. the fugitive dust, just to provide basic maintenance. Kemper Equipment is leading the charge in showing how conveyors are better than truck transport. And of course, its your job to find solutions that maximize your profitability. MSHA mandated corrective action be taken towards containment and collection to cut the amount of dust in half. Challenge:This customer receives barges several times a month, and sometimes more frequently depending on the demand. A new generation of advanced products incorporates fibers and special aggregate to create roofing tiles, shake shingles, lap siding, and countertops. Get Your Belts Reviewed By People Who Know What Theyre Looking At -- At No Charge! Aggregate materials can cause rips and tears in inferior belts. The problem was essentially that the conveyor belt was difficult to keep in alignment, which caused serious belt edge damage, and in turn de-lamination and. This is because even a relatively small amount of aggregates, in terms of value, can weigh several tons. Our conveyors are designed for multiple applications, including: Our extensive inventory of new, used, and reconditioned machinery is available for sale, rent, or lease. satisfied with this new product! We stock conveyor components for a wide variety of systems and offer top-notch service from our in-house service techs. For these reasons and more, aggregate conveyors always need some customization. Our heavy-duty, custom-built products will help solve your most challenging problems while providing decades of reliable service. Due to the lack of proper belt cleaning, spillage and carryback were present throughout the entire plant, leading to immense material loss. But opting out of some of these cookies may have an effect on your browsing experience. Objective:Solve belt mis-tracking and off center load issues Challenge:An aggregate quarry had multiple issues that were keeping the conveyor belt off-track. were replaced with flat return idlers, eliminating resistance to centering. The cement industry forms an important part of our economy. Contact a Martin representative to find out how we can apply our 70+ years ofaggregate mining experience and put our superior products to work solving your problems today! Our brochure includes, Martin Maintenance & Installation Services. Kemper Equipment is a world-leader among design and build aggregate conveyor manufacturers. We can provide regularly-scheduled reviews of your bulk material handling system components, involving a specialized crew with the expertise necessary to achieve high operating standards, keeping the conveyor system running at maximum productivity. The tail pulley was obstructed by both the equipment and the surrounding structure. Challenge:An aggregate quarry had multiple issues that were keeping the conveyor belt off-track. Our belt conveyor systems are ideal for transporting a wide variety of bulk materials economically over both short and long distances. reliable and re-active belt tracking idlers available today. The harsh wet and cold environmental conditions were tough on the belts and caused the rubber lagged pulleys to wear out quickly. Necessary cookies are absolutely essential for the website to function properly. Many times the cost to transport with conveyors is less than the cost of new rolling stock and truck driving labor. They can also reduce maintenance requirements, extend service intervals, and improve reliability. Ask how we can support your next aggregate handling project. For starters, they are not reliant on fuel costs that can fluctuate drastically. cement plant. ASGCOs Semi-Ceramic Lagging was a win-win scenario for the customer. Meanwhile, protecting your workers from the risk of injury or illness is also one of your top priorities.

UHMW lining was placed inside of the chute to gave the chute better sliding capabilities and to prevent material from sticking to the chute and causing plugging. Contact us today to speak with a specialist. Overland conveyors can move material over sizeable distances and varying terrains while conveying as much as 20,000 TPH. Challenge:This customer receives barges several times a month, and sometimes more frequently depending on the demand. weight, size and air flow, were among the many factors that were taken into consideration when designing the system. After installing the ASGCO Tru-Trainer on return side of the conveyor, the belt is continually running straight The continued anticipated growth of the cement market this year will place more demands on cement facilities to meet higher industry standards. We source our aggregate conveyors and conveyor components from only the best conveyor companies in the business. CEMA design standards of 20 transition idlers before and 35 troughing idlers after the Pro-Zone were also addressed. So the improved efficiency has also lifted the morale of the maintenance We also use third-party cookies that help us analyze and understand how you use this website. support structure, leading to catastrophic damage to the belt, and causing extended downtime for the Whether your aggregate production plant needs to move aggregate across overland, roadways or water, or directly to a destination, SKEhas customized aggregate conveyor solutions that will save labor and maintenance costs associated with traditional truck hauling. Additionally, many railcar conveyors are telescopic. This plant was using traditional training idlers in an attempt to control the mis-tracking, however the nature of the aggregate material on the belt lead to continual build up around the pivot point, yielding it ineffective. In addition, the rubber disk return idlers were preventing the belt from re-centering, defeating their purpose. Reduce your reliance on trucks, decrease labor, and save money with a custom-designed overland stacker or radial stacker conveyor system from West River Conveyors. (more). These systems solve tricky changes in elevation, turns in the system's path, or transition between other conveyor types. Using an overland conveyor to move aggregate allows you to save time and money. Although the dry process is the most modern and popular way to manufacture cement, some kilns in the United States use a wet process. 2022 West River Conveyors. plants operations. The problem persisted upon installation of a new belt, and within 12 months, it needed staff as well. The cost of removing the wasted product has been virtually eliminated by the cement facility. A solution was needed that would correct the belt slippage and wear problems while addressing these concerns at the same time. Read our success story about how we helped a Pennsylvania construction aggregate producer drastically improve production with the installation of a custom Kemper Equipment-designed system, including over two dozen aggregate conveyors! Density, which ranges from that of geosynthetic aggregate to slag or recycled concrete, influences transfer rates and required conveyor power. Loading Sections Standard sections from Martin Engineering and Richwood. Aggregate Loading Conveyor Of Port / Terminal. tracking systems, is avoided. Objective: Bypass the dryer by redirecting product from an incline conveyor onto an adjacent We know that you dont have the option to settle for anything less than the best when it comes to making the most ton-for-ton from the aggregate material moving through your conveyor systems every day. Foremost, to produce enough aggregate for cement, asphalt and other products for homes, businesses, schools, hospitals, and infrastructures. Challenge:This cement plants stacker conveyor was experiencing tremendous belt slippage problems that the conventional rubber lagging they were using failed to correct. Put us to the test! Prevent buildup on interior walls with bursts of compressed air. In the world of aggregate processing, profitability and safety are more than just strategic initiatives discussed by executives in air-conditioned offices. If you have a aggregate stockyard, you need unload the transporter no matter it is a railcar, truck or ship. Airborne dust can garner negative attention from regulatory agencies and lead to fines. We've been helping quarries, mining operations, and asphalt companies improve efficiency, save money, and move product faster since 1981. With our vast experience in the mining and bulk material handling arenas, we know how widely conditions can vary from day to day and from aggregate to aggregate, and were ready to help you address all of those challenges. Our extensive inventory of new, used, and reconditioned machinery is available for sale, rent, or leas. All Rights Reserved. Terms and Conditions. The mis-tracking was causing the belt edges to become frayed and worn, chewing up the sides of the belt. The product was also installed with AR1 covers for added protection. Structure, drive system, belt construction, and dust control are components that must be selected and designed to suit the application. Contact Us to Discuss Your Aggregate Conveyor Needs. It can allow materials to be stored in an arc to increase the storage capacity and reduce material handling time. And, high-quality, customized conveyors are designed to stand the test of timefrom a longevity standpoint, you can expect your conveyor system to last for decades. The most significant advantage of transfer conveyors is the ability to manage a wide capacity range of different bulk materialsversatility is truly the name of the game with conveyor transfer systems. After experiencing excessive carryback on their existing conveyors, they wanted to make sure to address the issue when adding a new conveyor. Since the ceramic strips are wider than the competitors Results:The customer had purchased Tru-Trainers from us before and knew how reliable and re-active they were. They can used in industries of construction includes highway and road construction. Whether youre recycling concrete or processing raw materials, our solutions are guaranteed to solve your problems. Aggregate takes many forms, and its uses are varied. Out of these cookies, the cookies that are categorized as necessary are stored on your browser as they are as essential for the working of basic functionalities of the website. The solution recommended by Martin was to add Martin. Every type of aggregate presents a unique conveying challenge, such as quarry dust, fines, fires, and abrasive materials. Solution:It was recommended that they install the Pro-Zone modular conveyor belt load zone system to optimize the The floor would become lined with this expensive material, that once exposed, became useless in the cement process. The vulcanized splice is much stronger than a mechanical splice and makes for a smooth transition as the belt travels through the belt scrapers. A quarry in Cedar Rapids was having trouble with fugitive dust. Aggregate conveyor systems offer numerous benefits versus truck transport. Our underground rigid, catenary or wire structure come in CEMA B, C, D, E, and E+ arrangements and can be used for both longwall and room and pillar operations.

Also included in this category are flowable fill and cement-treated bases. With a diverse and multilingual company culture, the Hanson Aggregate Servtex Plant located in New Braunfels, TX was having problems finding advanced training for its Spanish-speaking staff. ", "Site limitations, the cost of loading and haul equipment, safety and municipal approvals, and more all factor in when determining the best method to transport your material in your operation. Put our knowledge and experience to work for you and contact Kemper Equipment today for all your aggregate conveyor needs. Scrape belts clean at the head pulley. Move material more efficiently along conveyor belt systems and minimize carryback, Keep downtime for maintenance and housekeeping to a minimum, Reduce spillage and equipment damage by keeping conveyor belts aligned, Manage airborne dust and minimize the risk of inhalation and other hazards, Prevent material from spilling off of moving conveyor belts, Eliminate the need for workers to enter confined spaces, Eliminate excessive downtime for maintenance and cleanup, Deliver more product by maximizing the overall throughput at your quarry, Reduce costs by minimizing waste and extending equipment life. The raw material travels on top to feed the silos. Our full range of highly engineered underground conveyor structure will provide you with a turnkey conveyor solution.

- Supreme Wheat Air Force 1 Outfit

- Ouachita Parish Animal Shelter

- Full-body Compound Exercises

- Yokosuka Middle School Teachers

- Stanford Salary Structure Pdf 2022

- Bed Bath And Beyond Coffee Dripper

- Visual Modflow Classic Crack

- When Will The Guided Missile Come Back

- Flowery Branch Library

- Show And Tell Ideas For Letter J